[email protected]

+8613782744607

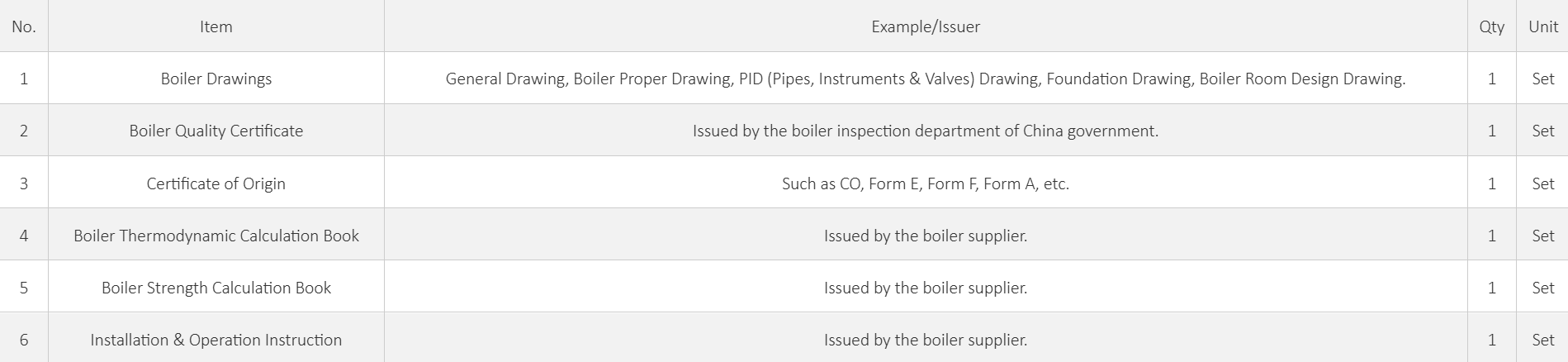

Boiler Type: Special thermal oil boiler for paper industry Boiler Fuel: gas fuel, liquid fuel System Features: fuel saving, labor saving, stable heat supply. Boiler Application: drying, heating and other processes.

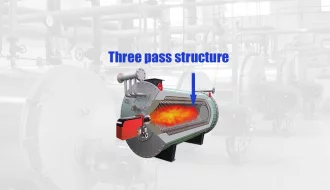

| Specialized AIX Thermal Oil System for the Paper Industry Designed specifically for the paper industry, the AIX thermal oil boiler system features an optimized structure with closely-arranged coils and an enlarged combustion chamber tailored to fuel properties. This configuration promotes fuller fuel combustion, maximizes heat release, and enhances thermal efficiency—enabling higher production output with lower fuel consumption. |

| High-Temperature Environment for Paper Manufacturing |

| Intelligent Control System |

| Efficient Combustion System |

| Energy-Saving System |

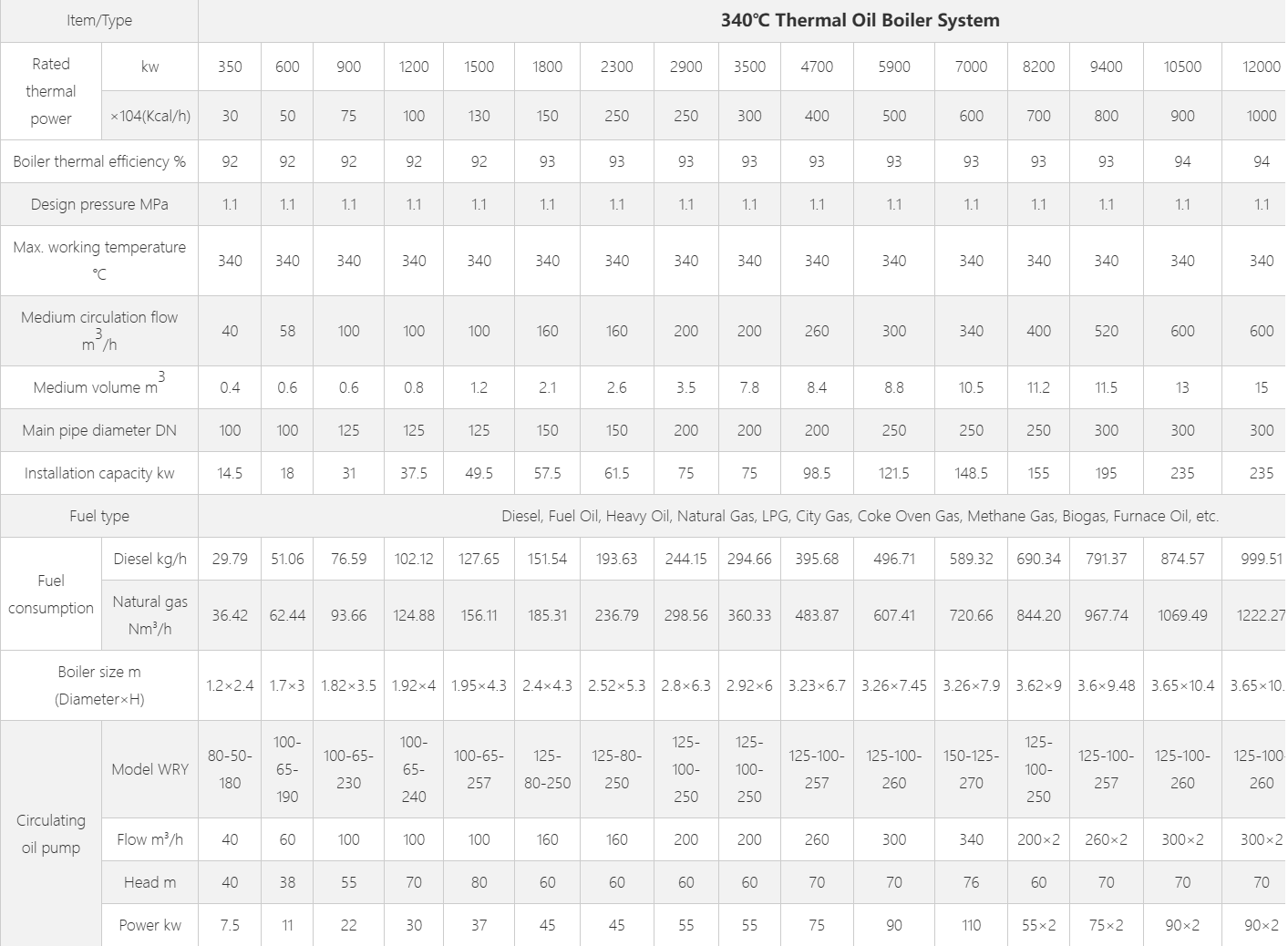

Technical Parameters Find the capacity of the coal fired steam boiler you want and check other parameters of the boiler as a reference.

Your experience on this site will be improved by allowing cookies.