[email protected]

+8613782744607

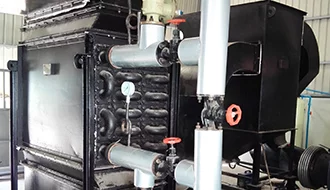

Capacity: 1~20T/h Pressure: 1.0 ~ 2.5 MPa Fuel: Bituminous Coal, Soft Coal, Anthracite, Lignite, Poor Coal, etc. Application: Food Plant, Paper Mill, Textile Plant, Chemical Plant, Printing and Dyeing Plant, Paper Mill, Oil Processing Plant, Fish Meal Plant, Power Plant…

| Three-Pass StructureThe AIX boiler features a single drum horizontal three-pass design with a spacious furnace, ensuring ample heating surface and sufficient steam output. The incorporation of spirally corrugated tubes enhances heat transfer, boosting thermal efficiency. |

| AIX Boiler Chain Grate Utilizes a movable chain grate tailored to the specific fuel characteristics of users, with options like small-scale grates or reciprocating grates. The grate design minimizes gaps, reduces coal leakage, and withstands high temperatures up to 1200°C. |

| Refractory Materials The boiler’s furnace walls are constructed using high-quality, high-temperature refractory bricks and cement. The outer shell is insulated with aluminum silicate plates, preventing smoke leakage and minimizing heat loss. |

| Economizer System Equipped with a high-efficiency economizer and dust collector, the system recovers heat from flue gas, lowers exhaust temperatures, and enhances thermal efficiency. It also ensures that pollutant emissions comply with national environmental standards. |

| Electrical ControlSystem AIX offers flexible electrical control options with multiple interlocking protections. Users can choose between a user-friendly, durable button-type control box or an intelligent PLC touch-screen interface that visually displays combustion conditions in real time. |

Technical Parameters Find the capacity of the coal fired steam boiler you want and check other parameters of the boiler as a reference.

Item/Type | EPCB Easy to Operate Chain Grate Boiler for Sale | |||||||||

Rated capacity t/h | 1 | 2 | 4 | 6 | 8 | 10 | 12 | 15 | 20 | |

Rated steam pressure MPa | 0.7/1.25 | 0.7/1.25/1.6 | 1.25/1.6 | 1.25/1.6 | 1.25/1.6 | 1.25/1.6 | 1.25/1.6 | 1.25/1.6 | 1.25/1.6 | |

Rated steam temperature ℃ | 170/194 | 170/194/204 | 194/204 | 194/204 | 194/204 | 194/204 | 194/204 | 194/204 | 194/204 | |

Feed water temperature ℃ | 20 | |||||||||

Boiler thermal efficiency % | 78.1 | 80.2 | 82.3 | 82.5 | 82.5 | 82.9 | 82.9 | 83.1 | 83.1 | |

Body heating area m2 | 22.99 | 48.7 | 96.34 | 148.15 | 174.4 | 226.2 | 276 | 374.5 | 669 | |

Fuel & consumption | Fuel type | Class II Soft Coal, Biomass, Wood Chips, Wood Pellets, | ||||||||

Coal kg/h | 118.76 | 231.30 | 450.79 | 674.54 | 899.39 | 1118.81 | 1342.57 | 1674.18 | 2232.23 | |

Biomass kg/h | 171.63 | 334.27 | 651.48 | 974.85 | 1299.81 | 1616.92 | 1940.30 | 2419.54 | 3226.05 | |

Size of boiler largest parts | Length | 4600 | 5800 | 6700 | 7000 | 7300 | 7600 | 7600 | 8500 | 9500 |

Width | 1900 | 2600 | 2700 | 3000 | 3000 | 3200 | 3200 | 3400 | 3800 | |

Height | 2900 | 3500 | 3500 | 3500 | 3500 | 3500 | 3500 | 3500 | 7100 | |

Weight of boiler | 18 | 22 | 30.1 | 40 | 21/14 | 23/17 | 23/19 | 21/24 | 25/24 | |

No. | Item | Example/Issuer | Qty | Unit |

1 | Boiler Drawings | General Drawing, Boiler Proper Drawing, PID (Pipes, Instruments & Valves) Drawing, Foundation Drawing, Boiler Room Design Drawing. | 1 | Set |

2 | Boiler Quality Certificate | Issued by the boiler inspection department of China government. | 1 | Set |

3 | Certificate of Origin | Such as CO, Form E, Form F, Form A, etc. | 1 | Set |

4 | Boiler Thermodynamic Calculation Book | Issued by the boiler supplier. | 1 | Set |

5 | Boiler Strength Calculation Book | Issued by the boiler supplier. | 1 | Set |

6 | Installation & Operation Instruction | Issued by the boiler supplier. | 1 | Set |

Your experience on this site will be improved by allowing cookies.