[email protected]

+8613782744607

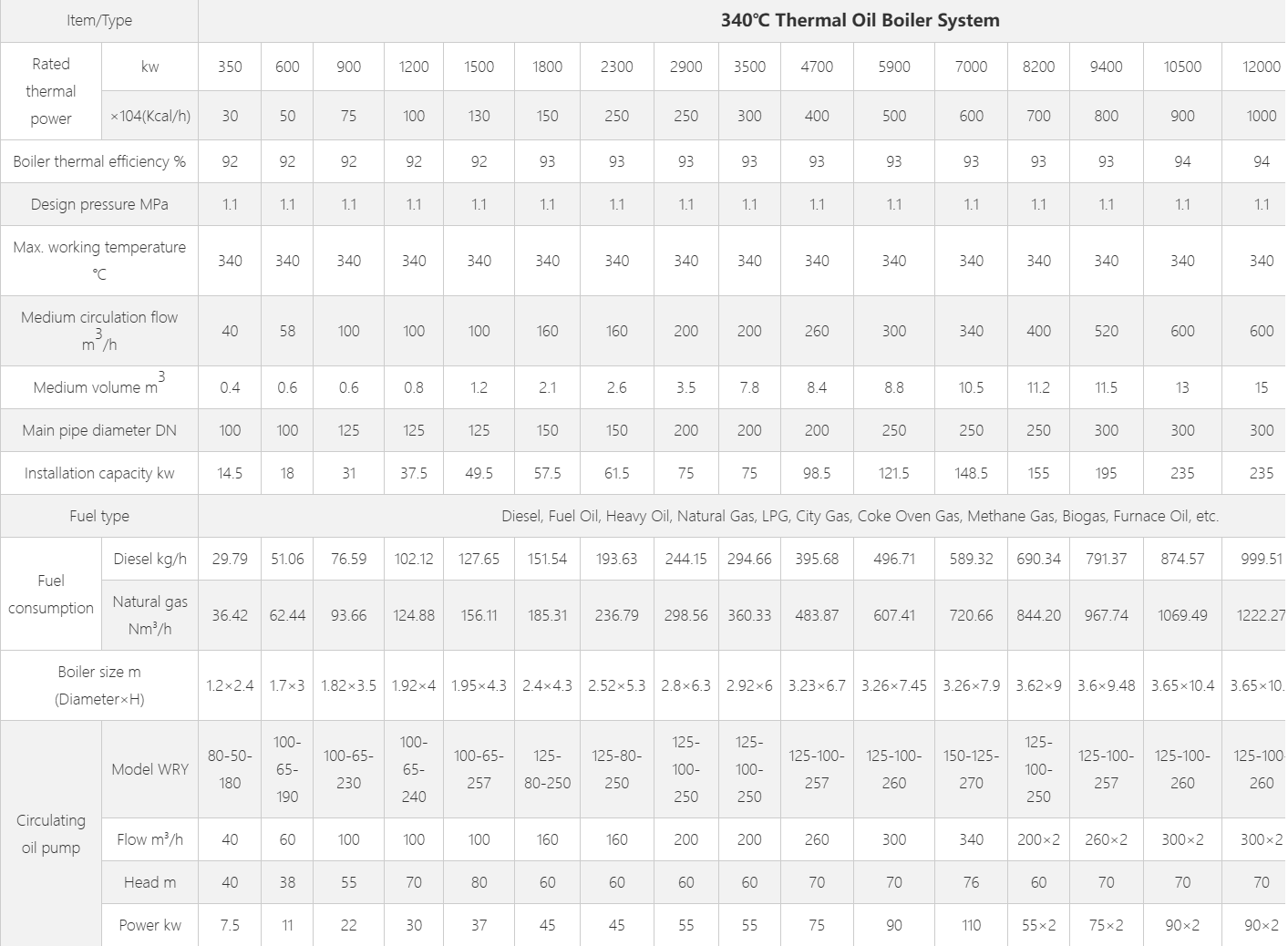

Boiler Type:High Temp Special Thermal Oil Boiler System Boiler Certification: CE, EAC, GB, ASME, Every you want to get. Boiler Performance: Durable, Reliable, Boiler Fuel: Diesel, Natural Gas, heavy oil, LPG, etc.

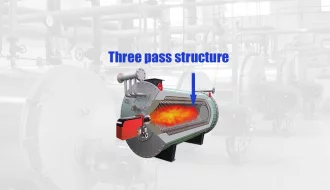

| High temperature thermal oil boiler structure The high-temperature thermal oil boiler features a compact coil design that creates a multi-stage heating environment inside the boiler. High-temperature thermal oil is directed from the outer coil layers to the inner layers via an oil distributor. The oil flows at high velocity while maintaining a stable temperature tailored to the factory’s requirements, ensuring a continuous and reliable high-temperature environment for industrial production. |

| System CompositionThe high-temperature thermal oil boiler system can be customized according to the specific thermal energy needs of the factory, with maximum oil temperatures reaching up to 340°C. It efficiently utilizes fuel-generated heat across various aspects of production. We also offer end-to-end service support, ensuring the entire system delivers a steady and uninterrupted high-temperature environment for your manufacturing operations. |

| Control SystemThe control system integrates electronic components from world-renowned brands such as Siemens and Schneider. Through specialized programming, an embedded chip collects operational data from the thermal oil boiler system and displays it on a computer or LED screen. This offers an intuitive overview of system performance and simplifies operational control. |

| Combustion SystemThe combustion system of the high-temperature thermal oil boiler is designed based on the physicochemical properties of the fuel. Common features include the use of world-class burners from suppliers such as Riello and Patek. These systems are highly intelligent and integrate seamlessly with the control unit, ensuring more efficient fuel combustion and greater heat output. |

| Energy-Saving SystemAligned with the factory’s production processes, we transform the heat energy generated by fuel into various forms of energy required for operations—such as steam, hot water, and electricity—in addition to heating thermal oil. This integrated approach maximizes fuel utilization and forms a comprehensive system solution, ultimately reducing production costs during order processing. |

Technical Parameters Find the capacity of the coal fired steam boiler you want and check other parameters of the boiler as a reference.

Your experience on this site will be improved by allowing cookies.