[email protected]

+8613782744607

Capacity: 0.7~14MW Pressure: 0.7~1.0MPa Fuel: Bituminous Coal, Soft Coal, Anthracite, Lignite, Poor Coal, etc. Application: Central Heating, Restaurant, Hotel, Hospital, Greenhouse, Food Plant, School, Slaughterhouse…

|

The boiler is designed with riser pipes strategically placed on the left and right sides, promoting smooth, safe, and stable water circulation at the base, which enhances operational reliability and efficiency. |

|

Featuring threaded smoke tubes integrated within the boiler drum, this system boasts a compact structure with a reduced overall footprint. Its lightweight construction significantly lowers the investment required for boiler room infrastructure. |

|

The incorporation of arched tube plates effectively reduces thermal stress, while advanced welding techniques at the threaded smoke tube ends and seams ensure robust connections, eliminating the risk of tube plate cracks for long-term durability. |

|

Equipped with a high-quality chain grate offering a high degree of automation, the boiler allows for the selection of grates tailored to the customer’s specific fuel characteristics, ensuring optimal combustion and fuel efficiency. |

|

This versatile boiler is well-suited for a wide range of industries, including rubber manufacturing, textile production, food and beverage processing, dairy production, canning operations, chemical fiber manufacturing, and industrial washing facilities. |

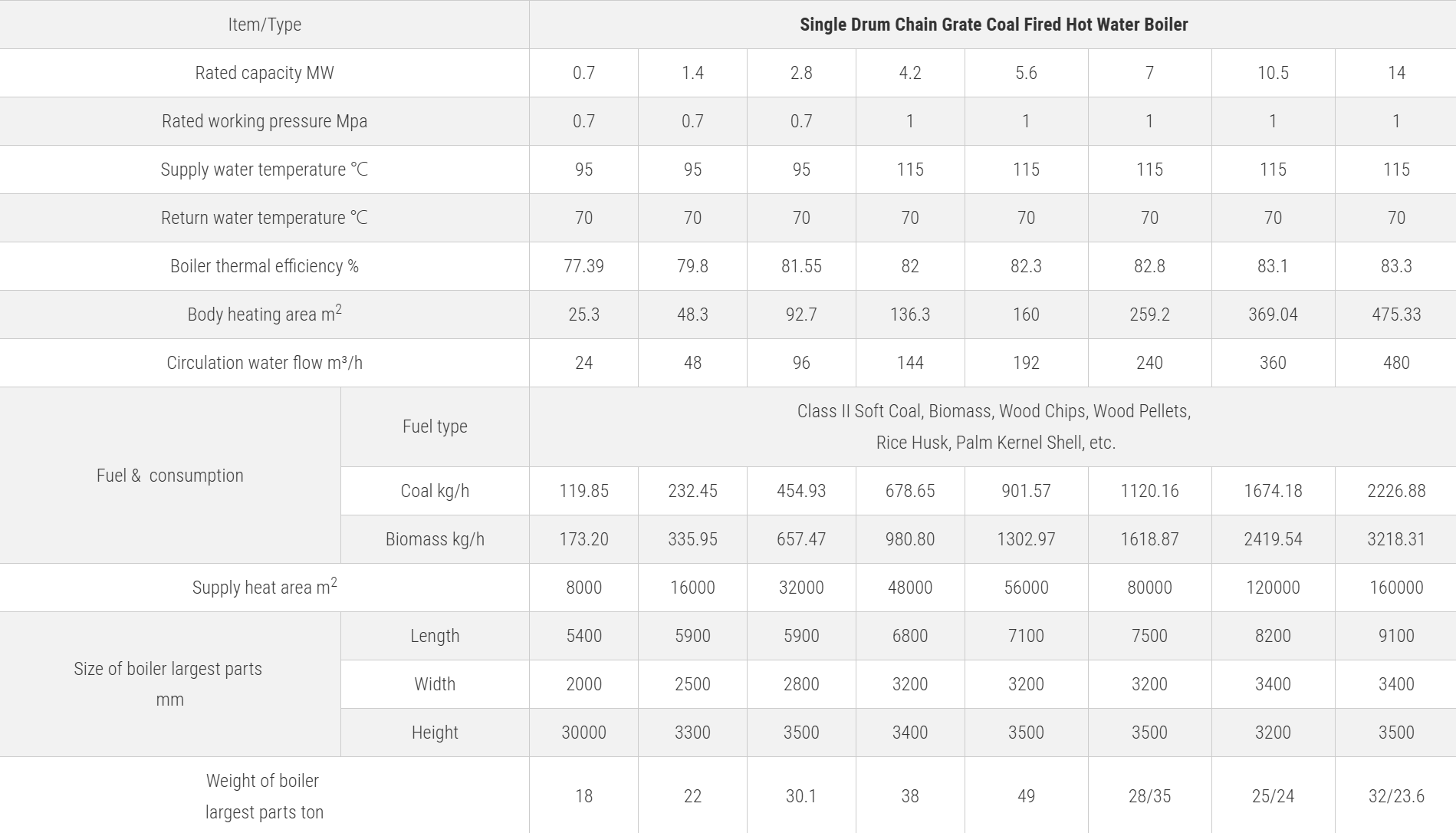

Technical Parameters Find the capacity of the coal fired steam boiler you want and check other parameters of the boiler as a reference.

Your experience on this site will be improved by allowing cookies.